1. Airframe

An Aircraft Maintenance Engineer (AME) plays a critical role in ensuring the safety, reliability, and efficiency of aircraft. They are responsible for inspecting, maintaining, and repairing various systems and components that make up the aircraft. These systems and components are crucial for the aircraft’s operation, performance, and compliance with aviation regulations. Here’s a detailed look at the main systems and components an AME typically works on:

The airframe is the physical structure of the aircraft, and an AME performs several tasks to ensure its integrity. Key components of the airframe include:

- Fuselage: The main body of the aircraft, housing the cabin and cockpit.

- Wings: Critical for lift generation, AMEs inspect and maintain the wings to ensure they are structurally sound.

- Empennage (Tail Section): This includes the stabilizers and rudders, which are essential for controlling the aircraft’s stability and direction.

- Landing Gear: The wheels, tires, shock absorbers, and other components of the landing gear must be inspected and maintained to ensure proper functionality during takeoff and landing.

- Flight Control Surfaces: These include ailerons, elevators, rudders, and flaps that control the aircraft’s movement during flight. AMEs inspect and repair these components to ensure proper aerodynamic function.

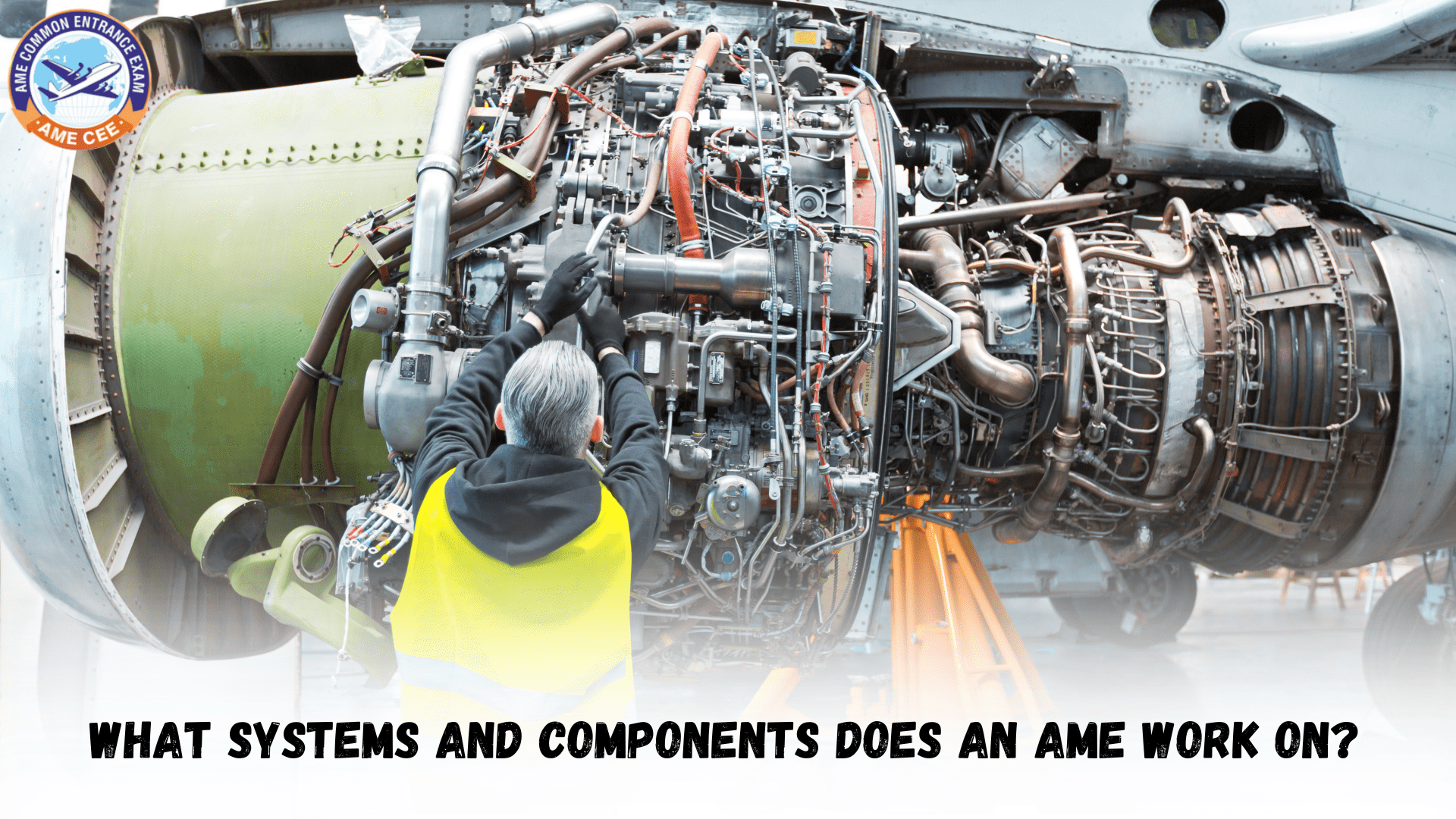

2. Powerplant (Engines)

The engines are the heart of the aircraft, providing the thrust needed for flight. AMEs work extensively on:

- Jet Engines: These include turbofan, turbojet, and turboprop engines. AMEs perform routine maintenance such as cleaning, inspecting, and replacing engine parts (e.g., turbine blades, compressors, and fuel nozzles).

- Engine Components: Parts like the engine starter, oil system, fuel system, and electrical systems must be inspected, repaired, or replaced to ensure engine performance.

- Propellers (for aircraft with propeller-driven engines): Maintenance of propellers involves inspecting for wear and tear, balancing, and replacing components like blades and hubs.

3. Avionics Systems

Avionics refers to the electronic systems used for communication, navigation, and monitoring during flight. AMEs working on avionics perform tasks such as:

- Radar and Weather Systems: Maintenance of weather radar, collision avoidance systems, and ground proximity warning systems.

- Flight Instrumentation: Ensuring that instruments like altimeters, speedometers, and attitude indicators are accurate and functioning properly.

- Navigation Systems: AMEs inspect systems like GPS, inertial navigation systems (INS), and autopilot, which guide the aircraft during flight.

- Communication Systems: Ensuring that the aircraft’s radio and satellite communication systems are functioning for clear communication between the aircraft and air traffic control.

4. Electrical Systems

Aircraft electrical systems are essential for powering various aircraft functions. Some of the components AMEs work on include:

- Batteries: Inspection and maintenance of the aircraft’s battery system, ensuring sufficient power for emergency situations and electrical load balancing.

- Electrical Wiring and Circuits: AMEs inspect and repair wiring and circuits that control lighting, instruments, and other electrical systems.

- Generators and Alternators: These provide electrical power to the aircraft’s systems during flight. AMEs ensure their efficiency and operational integrity.

5. Hydraulic Systems

Hydraulic systems in aircraft are used to control flight control surfaces, landing gear, and other critical mechanisms. AMEs perform maintenance on:

- Hydraulic Pumps: AMEs inspect and repair hydraulic pumps that provide power to flight controls.

- Hydraulic Lines and Valves: These need to be checked for leaks, wear, and proper operation, as they control critical systems like brakes, flaps, and landing gear.

6. Fuel Systems

The fuel system is critical to the aircraft’s operation. AMEs ensure the safe and efficient delivery of fuel to the engines. Tasks include:

- Fuel Tanks: Checking for leaks, damage, or corrosion in the fuel tanks.

- Fuel Pumps and Valves: AMEs maintain these to ensure proper fuel flow to the engines.

- Fuel Gauging Systems: Ensuring that the aircraft has accurate readings of remaining fuel levels during flight.

7. Environmental Control Systems

Environmental control systems regulate the conditions inside the aircraft cabin and cockpit, including air pressure, temperature, and oxygen levels. AMEs inspect and maintain:

- Air Conditioning Systems: Ensuring the cabin air is conditioned, especially during high-altitude flight.

- Pressurization Systems: Maintaining the pressurized cabin environment, essential for passenger safety at high altitudes.

- Oxygen Systems: Ensuring the onboard oxygen supply is functioning correctly, particularly for emergency use.

8. Landing Gear Systems

The landing gear system includes the wheels, brakes, tires, shock absorbers, and retracting mechanism. AMEs work on:

- Wheels and Tires: Inspection for wear and tear, and tire changes.

- Brake Systems: Ensuring the hydraulic or pneumatic brake systems are functioning properly, including checking brake pads, discs, and fluid levels.

- Shock Absorbers: The landing gear includes shock absorbers to cushion the landing impact, which need regular checks.

9. Anti-icing and De-icing Systems

To ensure safe flight during adverse weather conditions, AMEs maintain systems that prevent ice buildup:

- Wing and Engine Anti-icing: Preventing ice accumulation on wings, tail, and engines, which could affect flight performance.

- De-icing Systems: These systems use heated air or other methods to remove ice from critical areas such as the wings and tail before takeoff.

10. Aircraft Cabin Systems

Various systems inside the cabin ensure comfort and safety for passengers and crew. AMEs work on:

- Seatbelt and Emergency Oxygen Systems: Inspecting and maintaining safety equipment to ensure they function correctly in case of an emergency.

- Interior Lighting and Power: Ensuring the functionality of cabin lights, overhead bins, and power outlets.

11. Fire Protection Systems

Aircraft fire protection systems are essential for ensuring the safety of both the aircraft and its occupants. AMEs are responsible for:

- Fire Suppression Systems: These include engines, cargo compartments, and lavatories. AMEs ensure these systems are inspected and properly maintained.

- Smoke Detection Systems: These systems detect smoke in cargo areas, lavatories, and other sensitive zones, and AMEs ensure that these detection systems are operational.

12. Structural Components

Aircraft structures include elements that provide strength and stability, such as:

- Wings and Fuselage: Inspecting for cracks, dents, and corrosion.

- Rivets, Bolts, and Fasteners: Checking for looseness or damage.

- Composite Materials: Maintaining modern aircraft that use composites for lighter weight and durability.

Conclusion

An Aircraft Maintenance Engineer (AME) works on a wide array of systems and components, from the powerplant (engines) and airframe to more specialized systems like avionics, hydraulics, and fuel. Their job requires a deep understanding of various technologies and the ability to work with complex mechanical, electrical, and avionics systems to ensure the aircraft remains in peak operational condition. Whether conducting routine checks or repairing major components, the work of an aircraft maintenance engineering is essential for the safety and performance of the aircraft.